A New Age of Mower Conditioners

April 2015

David Noellsch works as a farm manager for a dairy cattle embryo transfer business, currently raising 3000 head of Holstein heifers near Fremont, Iowa. As a business in the development stages, with about 1500 acres of pasture and 500 acres of row crop, he’s been busy this year trying to put up as much hay as they can for the winter. As part of a limited launch for field evaluations, Noellsch used a Vermeer MC3700 Mower Conditioner to mow and condition his crop, and he says he has been pleased with what this new mower conditioner from Vermeer has to offer.

Initially, Noellsch says he was pleasantly surprised with the productivity of the mower conditioner.

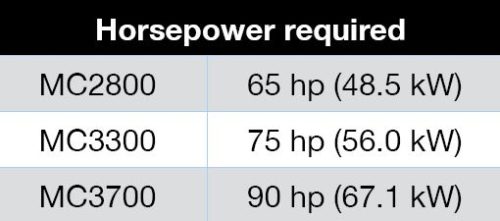

“When we first bought the machine, we were expecting to have to put a larger horsepower tractor in front of it,” Noellsch says. “With the mower conditioner we used before, we had about a 130-140 horse tractor on it. Right now, with the Vermeer mower conditioner, we’re running 120 horse, and it has no problem. I think you can even run it with a smaller tractor.”

Noellsch says that his fuel consumption is very little, and he estimated that he uses five gallons per hour on a smaller horsepower tractor.

Grounded in productivity and function, the new Q3TM Cutter Bar is designed to keep operators in the field. The modular cutter bar includes the Quick-Clip® Blade Retention System, Quick-ChangeTM Shear Ring and 3-year cutter bar warranty.

Noellsch says that while many features have proven themselves to be beneficial with the MC3700, it’s been the Quick-Clip Blade Retention System that he’s found most advantageous in his operation.

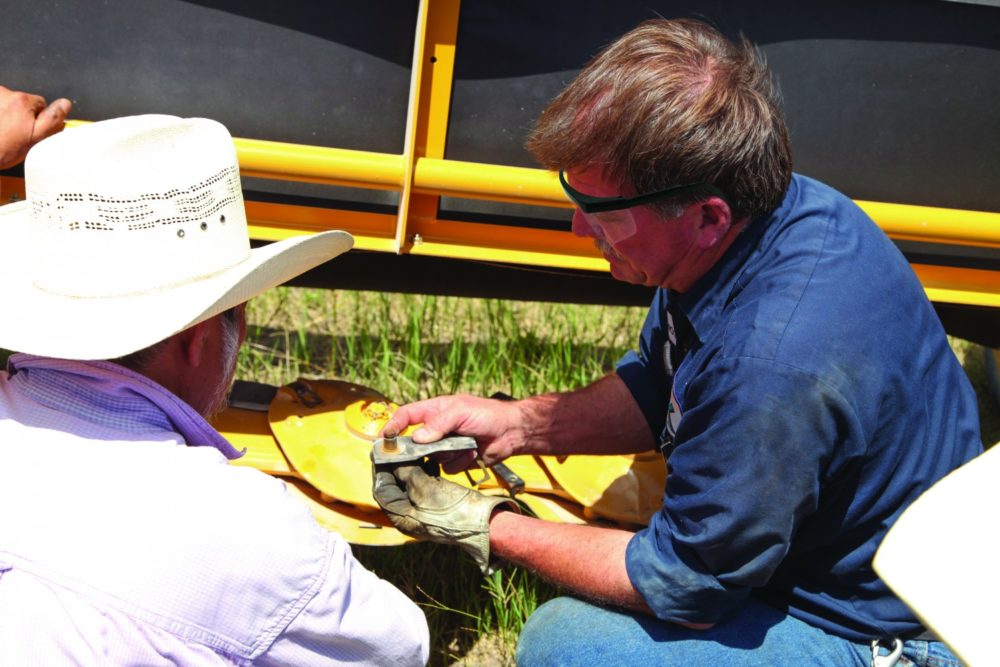

“The Quick-Clip system saves so much time,” Noellsch explains. “Our old trailed mower was a pain; if you didn’t have an impact wrench on hand, you had to constantly block the cutter bar so that it didn’t spin as you were trying to pry the bolt loose. The Quick-Clip has been really beneficial because all you have to do is pull out the provided tool, pop the clip loose, knock out the pin, and you’ve got ablade changed in 30 seconds. It’s much easier than fighting a stripped bolt or a nut that has no threads because you hit a rock. Its speed and ease of use has been a nice design that’s really helped our operation.”

Furthermore this new line of mower conditioners are equipped with a cutter bar protection mechanism, known as a shear ring.

The Quick-Change Shear Ring is a small ring with pins that sits within the disc hub. When a potentially damaging obstacle is encountered, the ring will shear protecting internal components. The ring itself, rather than the hub, can be easily replaced right in the field. As Noellsch can attest, this helps operators get back to mowing more quickly.

“We hadn’t ever used a machine that had the shear mechanisms in it,” Noellsch says. “It’s been a real benefit, though. As we go over uneven terrain and uncharted territories we’re finding posts and chunks of rock here and there, and instead of hitting those and ruining the machine we have a mechanism that helps us out.

“When you run into a problem, you basically have two bolts to pop off the top and one nut to take off. The process to remove it only takes about 10-15 minutes. You can then put in a new ring and keep ahead of the baler with no problems.”

Providing consistent weight on the cutter bar throughout the full range of motion, a nitrogen-charged accumulator suspension system allows for customized suspension settings for field conditions. More consistent suspension means less cutter bar weight on the ground and less stress on the header and framework when compared to a traditional mechanical spring system.

“Vermeer Mower Conditioners have a suspension system with adjustable down pressure, and I think that really is an advantage for us since our terrain is very hilly,” Noellsch explains. “We have a lot of pasture that hasn’t been mowed for hay before, and it was especially helpful with the muddy conditions we had this past spring. We were able to adjust the height and actual tilt of the mower and that adjustability allowed us to get into places where you’d normally get stuck with any other mower conditioner.”

In addition, Noellsch found that the suspension system contributed to a higher quality of cut. “With the system, you aren’t bouncing around and when you aren’t bouncing around you don’t get the uneven high spots where you went over the cut. The suspension system follows the contour of the ground a lot better.”

When the suspension needs to be adjusted, Noellsch says he has been impressed with the ease of which this is done.

“We’ve probably adjusted the suspension system three or four times now, and it’s very simple,” Noellsch says. “The ease of adjusting is as easy as pulling a lever on the tractor, filling the pressure up and releasing it through the valve on the mower. It’s been something that’s really easy to do in the field.”

When it comes to conditioning, Vermeer mower conditioners are available with a steel roller conditioner or a free swinging, steel v-tine conditioner. The v-tine conditioner features an adjustable concave plate that allows the operator to set the aggressiveness of the conditioning. This simple conditioning mechanism scrapes the surface of the crop to help decrease dry time. The steel roller conditioner offers an aggressive profile that allows for consistent conditioning across the roller. With the ability to break down tougher crops, the steel roller can also be adjusted for gentler conditioning on leafy, alfalfa crops.

For his operation, Noellsch says he prefers the steel roller conditioner.

“I think conditioning with the steel rollers is a lot better than other rollers we’ve used,” Noellsch says. “For the clover content we have, I really like using the steel rollers, and when we plant summer crops like sorghum sudangrass, the steel really helps in terms of keeping the leaf content so we do not lose a lot as we’re mowing.”

The flexibility associated with the Vermeer Mower Conditioners does not end with the roller/tine conditioner option. The crop forming control allows operators the ability to choose what size they want to make their windrows. With multiple swath adjustment options, users have the control to make a windrow narrow for baling directly behind the mower or wide for a quicker dry time. Noellsch says he finds this versatility to be especially helpful for his operation.

“We will probably adjust three or four times a day,” Noellsch says. “It’s as simple as loosening a handle, moving the panel and tightening it back up. It takes 30 seconds max. We’ll set some grass down for silage, set another row down for hay and adjust back and forth as the baler catches up.”

When it comes to doing maintenance on the Q3 cutter bar, the Vermeer Mower Conditioner line boasts of convenient cutter bar access. The unique hood design makes accessibility to the cutter bar quick and easy, and spring-loaded hoods keep weight light, so little effort is required to lift. Magnets in the curtain also help keep it out of the way while upkeep is performed.

“It’s been great to have easy access to the cutter bar,” Noellsch says. “The mower has flip-up tops and magnetic holdback for curtains. You can flip all the panels out of the way and you don’t really have to get under anything. You’re always out in the open working on the bar.

“Everything is fairly easy to grease and get to, there are only a few points that you have to keep up with. Initially, I figured that with a system this complex and with this many moving parts there would be a lot more areas to grease.”

Productivity, flexibility and convenience. It’s with the combination of these three features that Vermeer is presenting a powerful new line of mower conditioners. But don’t just take our word for it.

“I think if anyone can put this mower conditioner to the test, we’ve really done that on this farm,” Noellsch says. “Especially with uncharted ground, it’s gone through a number of dips and dives, and it’s held up really well. I’ve seen very little wear in terms of running gear. We have the normal maintenance parts like blades we change, but other than that, everything holds up excellent.”

Read More: Two Supreme Teams, One Superior Product