Hay tedders: How do tedders work to shorten dry-down time

December 2024

Why would you need a hay tedder? The spring and early summer months of 2024 underscored exactly that.

In the Midwest and other regions, the wet weather was seemingly unrelenting. If you’re in the haymaking business, that’s meant prolonged dry-down times and potential hay nutrient loss.

Tedding hay in high-humidity environments or during wet weather helps save time and preserves hay quality.

“Tedding helps tremendously when rain is heavy, and even when it isn’t,” said Hank Majeski, a Vermeer territory manager who specializes in forage equipment. “On the East Coast, we have high humidity and dew settles overnight throughout the season. A tedder is an absolute must in places like that, every year. Increased rainfall in typically dry climates, which is certainly welcome, can cause delays in haymaking. Having a tedder can cut your dry-down time significantly when the haymaking window opens.”

Is tedding hay worth it? Let’s review how and why you should consider a hay tedder.

How do hay tedders work?

Hay tedders are not something recently dreamed up. They’ve been around for over 100 years, dating to the mid-19th century. But the last several decades, tedders have enjoyed a resurgence, particularly in the United States.

The science behind tedding is simple. It lets nature do the work. Tedding hay is a process where you essentially fluff the crop – lifting and separating the crop to hasten dry-down times.

In doing so, you help reduce the nutritional losses in downed hay and forage.

“The sun and the air do the work more efficiently once you’ve run your tedder through the field,” Majeski said.

Vermeer tedders: The hook tine advantage of drying hay

Vermeer tedders feature a major advantage thanks to their hook tines.

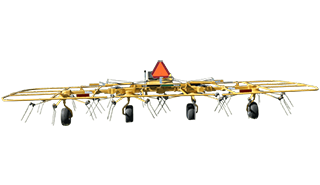

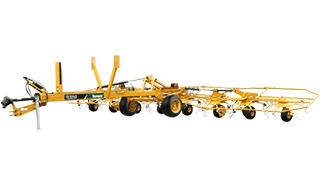

Vermeer TE-series tedders feature this technology, allowing them to pick up and spread a larger amount of crop than traditional straight-line tedder. These machines have tedding width options of between 17 ft and 33.5 ft.

“With the hook tine, we are able to flip the hay while also scattering it,” Majeski said. “This allows that green and often damp crop, that is on the bottom of the windrow, to get better sun and air exposure. If you watch our hook tine tedders in the field, you’ll notice the crop looks like a rooster tail behind the tedder. This lofting of the hay often creates what I call a ‘tenting effect’ when it lands.”

“Basically, the hay stands up a bit, giving the sun and the air more ability to work its magic.”

Learn more about the Vermeer hook tine advantage

How does tedding hay help nutritional value?

Beyond allowing for a shorter haymaking window, tedding hay can help reduce nutrient loss.

By spreading out downed crop, hay tedders preserve nutrients and reduce harvest loss by limiting the amount of plant respiration. Tedding hay also maintains the moisture content of the crop — meaning fewer wet slugs in bales and more consistent bales.

“When you create an even and timely dry down across a field, you create consistent forage that is less likely to spoil,” Majeski said. “Not having that crop laying in the field too long, where it loses nutritional value, is also important. Tedding can certainly help with this by speeding up dry-down time.”

Check out our lineup of Vermeer hay tedders

With a rich history of more than 75 years, Vermeer is your forage expert. Vermeer tedders offer everything from machines for occasional use like the TD100 tedder to others that are meant for heavy-duty workloads like the TE3310 tedder.

You can check out our full lineup for Vermeer hay tedders.

Contact your local Vermeer forage dealer to learn more about hay tedders available.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications. Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. © 2024 Vermeer Corporation. All Rights Reserved.