Meet the Vermeer manure spreader lineup

October 2025

When it’s time to haul manure, operators need equipment that is reliable, durable and gets the job done efficiently. Vermeer manure spreaders are built to meet that need, adding a robust lineup of machines to the Vermeer hay and forage family.

Built with industry-leading technology from Bunning, a company with a four-decade legacy in building premium spreaders, these machines are ready to work.

“Getting into the manure spreader market represents a natural progression for Vermeer,” said Mitch Field, a Vermeer territory manager. “We want to be that one-stop shop for customers, from feeding cattle to putting up hay and then hauling the manure away. It streamlines everything for both dealers and customers.”

Vermeer partners with Bunning for proven manure spreader technology

The collaboration with Bunning brings their well-established manure spreader expertise to the North American market. The company’s reputation for quality construction and reliability made them an ideal partner for Vermeer.

“When we announced the joint venture with Bunning, dealer response was immediately positive,” Field said. “Many of our dealers were already familiar with Bunning equipment. The feedback had consistently been excellent regarding build quality and reliability.”

If you’re looking for a manure management solution that’s built to last, contact your local Vermeer agriculture dealer.

Two distinct manure spreader series for different farm operations

The Vermeer manure spreader lineup consists of two distinct series designed for different operational scales and requirements.

MS-series: Small manure spreaders built for smaller operations

The MS series targets small to medium-sized operations, with models engineered for farms that may not have large tractors available.

“The MS-series manure spreaders targets cow-calf operations and smaller farms that may only have 150-hp (112 kW) tractors available,” Field said. “Previously, some farmers needed big tractors and equipment to justify purchasing a manure spreader. Now we can serve smaller operations with equipment that matches their scale.”

MSC-series: Large manure spreaders built for commercial operations

The MSC-series manure spreaders serves high-capacity operations and custom applicators with larger models that require more horsepower. These units are built for maximum capacity and day-in, day-out performance. The MSC line also incorporates advanced technology, including optional load cells for real-time weight monitoring, ISOBUS compatibility and GPS capability for variable rate application and precision spreading.

How to choose the right size manure spreader

Several factors influence equipment sizing decisions, including your location, tractor availability and management practices.

“Area and available time windows dictate sizing requirements,” Field said. “Farmers in southern regions might have longer spreading seasons and can manage with smaller equipment. But in northern climates where you have just two weeks in spring or fall for manure application, operators often choose larger capacity machines to complete the job quickly.”

Spreader applications across livestock sectors

Twin vertical augers for wet material

The twin vertical auger (TVA) system is the ideal solution for the wet, heavy bedpack material typical of cow-calf operations.

“For most cow-calf operations dealing with bedpack material, the twin vertical augers are the ideal solution,” Field said.

The system provides a consistent flow and a wide, even spread pattern.

Additional spreading options

For operators who only occasionally spread dry material, a simple canopy can be added to a TVA system for optimized spread consistency.

Engineering features that deliver durability

Fully welded construction

The fully welded body design prioritizes long-term durability. While some competitors use bolted panels, the solid welded construction eliminates potential failure points and prevents moisture from getting inside and causing corrosion.

“The fully welded construction sets these spreaders apart,” Field said. “Some competitors might look fancier with their poly panels and bolted assemblies, but Vermeer solid welded construction eliminates potential failure points. There’s nothing that can break loose or separate.”

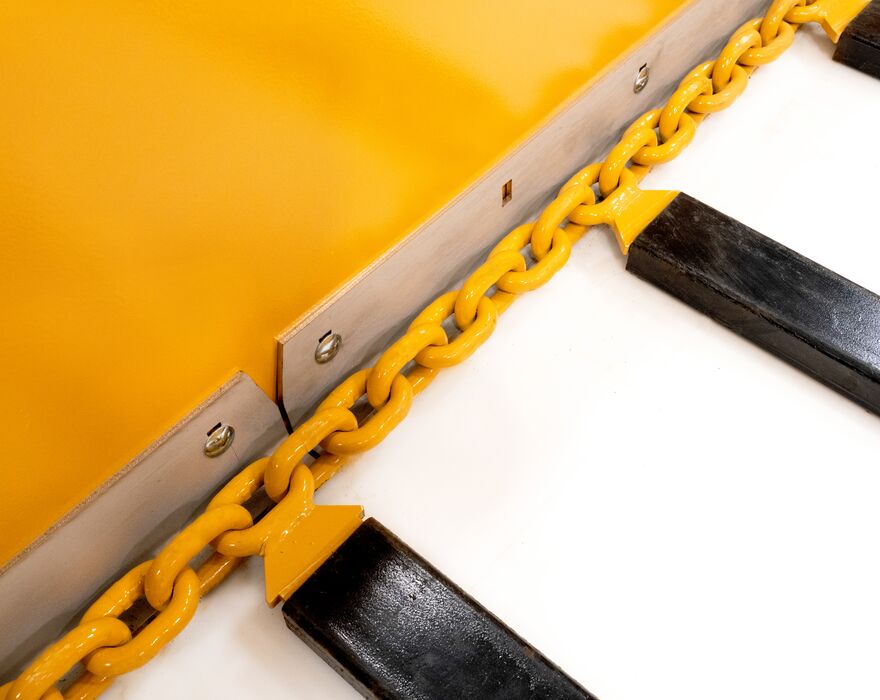

A chain system that reduces maintenance

Chain problems are one of the most frustrating aspects of spreader ownership. The Vermeer design uses a single, heavy-duty chain with a socket-fit slat system that addresses this issue.

“Traditional chain designs require daily tightening, which becomes a major hassle,” Field said. “Our single-chain design with socket-fit slats eliminates this problem. If a slat bends, it simply slides off the chain without derailing the entire system.”

This design also makes repairs much simpler, allowing work to be done from the side of the machine instead of from underneath.

Heat-treated steel for component longevity

Critical wear components are made from heat-treated boron steel to handle the inevitable rocks and debris found in manure. This advanced metallurgy provides flexibility and durability where it’s needed most.

“When small rocks pass through the system, the auger flighting flexes without bending permanently, then returns to its original form,” Field said. “Meanwhile, the boron steel beater teeth show dramatically less wear than traditional materials.”

The Vermeer competitive advantage

The main benefit of Vermeer manure spreaders is their proven reliability and durability that comes from combining the best construction features into a single, dependable machine.

“When you compare different manufacturers, each might excel in one or two areas,” Field said. “Some have good chain designs but use poly construction. Others have welded bodies but inferior chains. Vermeer combines the best features into a single, superior product.”

This approach, backed by the strength of the Vermeer dealer network, delivers a machine that’s built to work.

Find your manure spreader solution

While Vermeer manure spreaders are a premium product, their value is measured in reliability, extended service life and comprehensive dealer support.

“The question for farmers is: How much is it worth to be able to hook up and work without worrying about breakdowns?” Field asked. “When you only have a two-week window for manure application, reliability becomes critical.”

About Vermeer Corporation

Vermeer delivers a real impact on the way important work gets done through the manufacture of high-quality agricultural, underground construction, surface mining, tree care and environmental equipment. With a reputation for being built tough and built in a better way, Vermeer equipment is backed by localized customer service and support provided by independent dealers around the world. To learn more about Vermeer, products, the dealer network and financing options, visit vermeer.com.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region.

Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. © 2025 Vermeer Corporation. All Rights Reserved.