People Behind the Product: Mike Buban

April 2015

Vermeer is the story of people and equipment dedicated to improving the infrastructure that keeps us connected, working farms and ranches that nourish our food supply and managing our natural resources responsibly. To give you a more in-depth look at the people behind our products, we sat down with some Vermeer team members. Today we’d like you to meet Mike Buban.

Name: Mike Buban (pictured far right with colleagues Sarah Pfoltner and Dave Pealer)

Hometown: Centerville, Iowa

Graduated from: Iowa State University

Years with Vermeer: Just over 10

Current Position: Senior technical writer

Makin’ Hay: In a few words, tell us what it is that you do.

Mike Buban: My team and I deal with several things that people in the field see. All engineering or service documents go through my group to get to the field. Parts, operator, maintenance and service manuals – that’s what we do, and in addition to that field-installed kit instructions, service bulletins and service notes. That basically encompasses my department, technical publications.

MH: Can you tell us what steps you take to put something like a parts manual together?

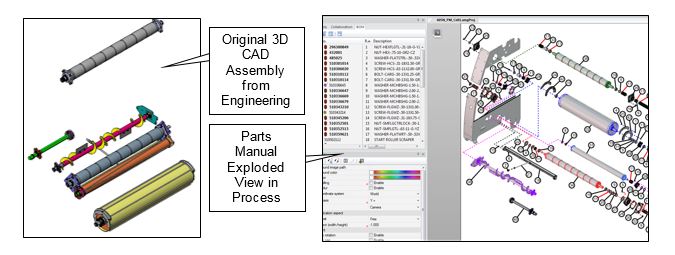

Mike: To make a parts manual, we start with the 3D CAD modeling – the 3-dimensional digital representations of all parts used in a machine – that engineering creates and uses to design the machine. Below, for example, is the start/drive rollers assembly used in the 605N baler. For any given machine there are any given number of assemblies. We take one of those assemblies at a time and we do what’s called an exploded view. We move all the parts outward from their installed locations and label them individually so that people can see each part and know what particular part they need.

MH: How long does it usually take to create a parts manual? Let’s say, the 605N baler for example?

Mike: Well, there are about 100 figures in that parts manual. On average, one person can do two to three figures per day. So that can take up to 50 days or 10 weeks of work. As for writing instructional documents like an operator’s manual, for example, it’s hard to put a number on that. Back in the day, I used to figure we could pretty well bank on taking six weeks for any given project. Now I usually figure something like two hours per page of written material if we’re creating a custom document from the ground up. Researching, creating content and creating graphics all takes time. I want to know whatever machine I’m working on at the engineering level because I want to know all the details first hand. That way, I can include all the information customers need to know so they can get the most out of their machine.

MH: What made you interested in this particular field?

Mike: It seemed like a good fit because my background is technical. I’m kind of a gearhead, and I like to know the details of how the machines work. The writing part is something I was coincidentally good at. It’s not like it’s something I studied; it’s just something that’s come naturally to me. The cool thing about technical writing is that as far as nouns, adjectives and verbs go, less is more.

MH: So what’s one thing you’ve had to learn along the way?

Mike: The thing I’ve had to learn more than anything is that any document we create is going to be some writing, but it’s going to be more graphics based. We really put the most work into the graphics that go with the text to explain things in a manual. I’ve had to get creative and learn how to make the graphics anyway I can, by any means necessary, including photos.

MH: What’s the greatest length you’ve gone to get an image for a parts manual?

Mike: Well, today we create most of our images with our 3D CAD interface, but we used to use a lot more photos. Seven or eight years ago, I was working on instructions for a wheel rake. We didn’t have 3D CAD available for that machine. All we had were 2D drawings, and so in order to create the assembly instructions, I went back to the shop and literally started building a rake and took pictures throughout the process so I knew exactly what was involved in the final product.

MH: Tell us about the most rewarding aspect(s) of your job.

Mike: We deal with everything in our department – anything forage related goes through us. It’s a manual process, no pun intended. Time is against us and we often have to work on projects from the ground up, but it’s still rewarding at the end of the day. I find the creation of a good graphic to be enormously satisfying. It’s also fun to go out and run equipment and work with equipment. That’s pretty darn rewarding. That’s where I learn the most – when I get my hands on a machine or go out and visit customers and understand the things they’re up against. Then I can incorporate those perspectives into my work to improve what I’m doing.

MH: Outside of work, what are some things you enjoy doing?

Mike: I play bass guitar and six-string guitar – either electric or acoustic, it just depends on the day as to what I like better. I’ve been playing musical instruments since I was in elementary school. Now I play in a couple different cover bands, in churches, at community events, and at any other events where live music appears on the playbill. I’m even in a band with a few different Vermeer employees that plays for the traditional employee potluck lunch at Christmas. It’s a fun and very rewarding hobby, less expensive than some, more expensive than others… When it all comes together right, it’s just pure magic.