Silage vs. hay: What is silage? Does silage improve feed quality and farm efficiency?

March 2025

Unpredictable weather. Tight harvesting windows. The constant push for higher production.

As a farmer, you’re all too familiar with these challenges. But what if there was a way to reduce your dependence on perfect haying conditions while potentially boosting your feed quality?

Enter silage — a method of preserving green forage crops for livestock feed that’s gaining traction among forward-thinking farmers. But is it right for your operation? And there’s a lot to consider when weighing silage vs. hay.

Let’s cut through the noise and explore how silage stacks up against traditional hay with insights from Ed Henning, senior product training specialist for Vermeer Forage.

What is silage?

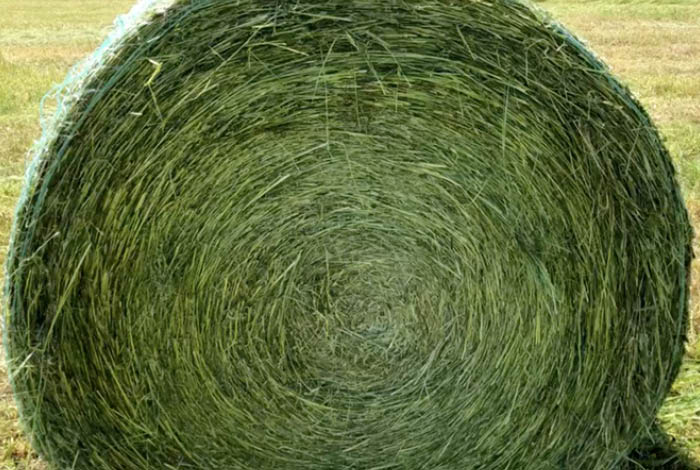

Silage is fermented, high-moisture forage made from crops like grass or alfalfa, including the entire plant. It’s preserved through fermentation in airtight conditions and serves as nutritious feed for cattle.

“The key to producing high-quality silage is minimizing air exposure during fermentation,” Henning said. “An anaerobic environment allows beneficial bacteria to thrive, breaking down plant sugars and producing lactic acid. This natural preservation method maintains and can even enhance the forage’s nutritional value.”

What crops can be used for silage?

Silage production offers farmers flexibility in crop choice, allowing them to make the most of their available resources and adapt to local growing conditions. Common crops used include:

- Grass: Various grass species can be used, offering a good balance of nutrients.

- Corn (whole plant): Known for its high energy content, corn silage is popular in many regions.

- Alfalfa: Valued for its high protein content, alfalfa silage is beneficial for cattle in general and commonly used in dairy operations

- Oats and wheat: These cereal crops can produce nutritious silage, particularly when harvested at the right stage.

- Sorghum: Drought-tolerant sorghum can be an excellent option in drier climates.

Silage vs. hay comparison

While both silage and hay are preserved forages, silage offers several distinct advantages. The key differences and benefits of choosing silage include:

Moisture content and preservation method

- Silage is baled at a higher moisture content (typically 25% – 50%) and undergoes fermentation in an anaerobic environment.

- Hay is dried to about 15% – 20% moisture and is preserved through this drying process.

- Benefit: This difference allows for greater weather flexibility in silage production, reducing dependence on extended dry periods for harvesting.

Harvest timing and nutrient retention

- Silage hay can be harvested earlier, often at the crop’s peak nutritional value.

- Dry hay requires longer field-drying time, which can lead to nutrient loss depending on varying conditions such as crop type, weather or length of time in the field.

- Benefit: Earlier harvest and fermentation in silage production preserve more nutrients, resulting in higher quality feed.

Leaf retention

- Silage production results in less leaf shatter compared to hay production.

- Benefit: More leaves are retained in silage, preserving nutrients that are often lost in hay production.

Palatability and animal preference

- Many animals prefer the taste of silage over dry hay.

- Benefit: Improved palatability can lead to increased feed intake and potentially better animal performance.

Storage efficiency

- Properly wrapped silage bales have lower storage losses compared to hay.

- Benefit: This can result in more usable feed and less waste over time.

“The flexibility of silage production can be crucial in regions prone to frequent rain, allowing farmers to harvest at the optimal time rather than waiting for a perfect weather window,” Henning said.

Considerations when choosing between silage and hay

While silage offers numerous benefits, consider these factors when weighing silage vs. hay:

- Hay equipment investment: Silage production requires specialized equipment, including mower conditioners, silage balers and bale wrappers. Vermeer offers a complete portfolio designed specifically for efficient silage production.

- Storage requirements: Silage bales need proper wrapping to create the anaerobic environment essential for fermentation. This wrapping must be completed promptly after baling to minimize spoilage and maintain feed quality during storage.

- Feeding management: Silage requires different handling practices than hay.

- Moisture content management: Crucial for successful fermentation.

- Market demand: Consider local preferences for silage vs. hay.

“Moisture content could range from 25% to 50%, with anything above mid-20s typically requiring wrapping for storage,” Henning said. “The key consideration was that longer drying times could lead to nutrient loss, so many farmers aimed to bale as soon as conditions allowed.”

Maximizing silage production with the right equipment

The Vermeer Pro G4 baler is designed to excel in silage production, offering features that optimize this process:

- 17-knife chopping system: Precuts the crop for smaller bites, minimizing feed loss and improving digestibility. Operators can select 0, 8, 9, or 17 knives from the cab for optimized bale density and silage quality.

- Atlas Pro™ control system: Monitors bale shape, adjusts density based on moisture and crop type, and provides real-time bale weight data. Allows customization for up to 50 fields.

- Netwrap system: Located at the rear for convenience, it spreads net edge-to-edge with adjustable tension. The Atlas Pro system monitors netwrap levels, alerting operators when to reload.

- Heavy-duty components: Large bearings, shafts, rollers, and chains ensure durability when handling wet, heavy crops. Features 100-diamond chain on the left and double-80-diamond chain on the right.

- Drop floor: Flexes to minimize blockages and can be opened hydraulically from the cab to clear plugs quickly, reducing downtime.

“Our 17-knife system provides flexibility in bale density and structure,” Henning said. “Many operators choose to use only half the knife bank, striking a balance between density savings and improved bale structure retention.”

Take a look at our comprehensive hay and forage equipment guide.

Benefits of silage over hay

While both play important roles in modern farming, silage’s flexibility and nutritional advantages are drawing increasing interest from farmers. Henning summed it up, “Many successful farms utilize a blend of silage and hay production to enhance flexibility and build resilience in their forage systems.”

Whether you choose silage vs. hay, having the right equipment is crucial for maximizing forage quality and operational efficiency. For farmers looking to optimize their feed production, the Vermeer Pro G4 Baler — with its advanced features specifically designed for this purpose — might be the ideal choice.

For more information about the Vermeer 504 Pro G4 baler or 604 Pro G4 baler, and to receive personalized support, reach out to your local Vermeer dealer today.

About Vermeer Corporation

Vermeer delivers a real impact on the way important work gets done through the manufacture of high-quality agricultural, underground construction, surface mining, tree care and environmental equipment. With a reputation for being built tough and built in a better way, Vermeer equipment is backed by localized customer service and support provided by independent dealers around the world. To learn more about Vermeer, products, the dealer network and financing options, visit vermeer.com.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications. Vermeer, Atlas Pro, and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries.

© 2025 Vermeer Corporation. All Rights Reserved.