Strong Stalks Call for Tough Equipment

September 2019

605N Cornstalk Special baler helps solve growing problem for corn, cattle producers.

Cattle producers have long found cornstalks to be an inexpensive addition to feed rations and a convenient, plentiful bedding source. They’re widely available, especially in areas heavy on row crop production. Additionally, baling cornstalks is a good way to clean up crop residue in a corn-soybean rotation area and preserve them to add to feed rations long after they would have been grazed down in the field.

But the advancement of corn genetics — specifically the advent of Bacillus thuringiensis (Bt) traits — has created some major challenges for the management of corn residue. Baling cornstalks today is more difficult than it’s been in decades past; many of today’s hybrids — especially those intended for acres where corn rootworm, European corn borer and stalk rot are potential robbers of corn yield — have much stronger stalks than in years past. Though each acre of corn is capable of producing more yield per acre, that output has caused the need for stronger stalks to support increased production, especially in the face of pests that target those stalks.

The result: Some cornstalks are rock-solid, challenging in-field residue breakdown and baling to use as a livestock feed ingredient later on. Making baled cornstalks today requires a baler that can handle increased rigidity and strength.

“I think it wasn’t just that we introduced and stacked these two Bt traits in corn. That gave us more resistance to European corn borer, which causes stalk rot, and corn borer, which causes lodging. But around 2005 to 2008, seed companies got a lot better. Plant health improved and we saw more resistance to the causes of stalk rot. Then, farmers started using fungicides to help the crop stay greener longer,” said Davidson Consulting Agronomist Dan Davidson. “We started seeing these traits get stacked on to better genetics, then all of a sudden, we had a crop that could stand really well, minimizing problems like wind damage, green snap and lodging. Since about 2010, all of these Bt traits have been adopted and we have a lot of plants that just don’t decay. We have 200-bushel corn crops that yield five tons of above-ground crop residue that doesn’t break down. In many cases, we have to help breakdown by hitting it with tillage, a stalk chopper, ripper or disc.”

Despite the challenges, cornstalks remain important to many cattle producers. Though their production is increasingly difficult, there’s value in baled cornstalks that makes baling them a worthwhile venture for both crop and livestock farmers.

“Cornstalks are a lower-value forage, but sometimes it’s your last chance of the year to put up any forage. Most producers aren’t putting up much or any hay in October and November,” said Vermeer Product Manager Josh Vrieze. “If you’re short of hay, cornstalks can help make up the difference, and some producers are actually fairly dependent on them. Some use baled cornstalks for bedding, while others use them in feed rations.”

Why this matters today

Yes, cornstalks aren’t the highest-value forage supply in the world, but they’ve become an integral part of cattle feed rations in parts of the country, specifically where there’s an abundance of corn acres and a high concentration of ethanol production. Ethanol coproducts — both wet and dry distillers’ grains — comprise a common protein source in many cattle feed rations in the Midwest, for example. Cornstalks represent a readily available fiber source for a balanced ration, according to Vermeer Territory Manager Bart Elder.

“Ethanol coproducts need a dry fiber source. You don’t need a lot, because you’re not asking for any energy from cornstalks, but they still offer the fiber necessary for a lot of these rations that are based on wet or dry distillers’ grains,” Elder said. “Yes, cornstalks are low-value, but when we’re looking for a dry fiber source, it’s not something producers want to spend a lot of money on. They’re paying for most of their feed ration in distillers’ grains.”

In addition to their use in in a feed ration, the removal of cornstalks from the field represents another value proposition for the producer. In continuous corn production systems, the removal of crop residue — especially today’s higher-strength stalks — is seen as a key component of maintaining balance in soil composition and nutrients.

“There are a lot of theories out there that indicate taking this residue off the field will increase yield,” Elder said. “It’s not a huge yield gain, but in many cases, it’s important to remove at least some of it, especially if it’s not breaking down like it has in the past.”

Solving the stalk strength problem in the field

With today’s stalk strengths, a solution has become a problem, albeit in an entirely different area of production. Stalks are tougher and stronger than they’ve ever been, and if you’re baling those stalks to use as feed later on, they’re likely tough on your equipment.

“If you look at the lower third of a cornstalk today, it’s just like wood. The strength of these stalks is evident in no-till fields, when there are still stalks on the ground from two years before,” Davidson said. “With no soil contact, they haven’t broken down.”

Effectively managing today’s cornstalks provides benefits to both cattle and crop producers but requires the right strategy and equipment.

Managing residue in the field

Solving the problem starts with finding the right residue management strategy. Depending on soil organic matter, carbon cycling and crop rotations, corn producers can take steps to ensure any stalks left in the field are able to adequately break down through environmental conditions and mechanical management.

For stalks left in the field, Davidson recommends approaching their removal or breakdown after harvest from a soil-first perspective. Determining what kind of soil activity you have will help determine whether that residue can break down naturally in the field or if it will need a jolt from a field operation, be it tillage or baling.

“If you have a very healthy soil profile with a lot of microbial activity, even very tough stalks will break down more quickly than in soils that have mediocre soil health,” Davidson said. “A very healthy soil with a lot of carbon cycling and combination of fungal and bacterial activity will help stalks break down more quickly.”

Managing cornstalks with the right equipment

In-field breakdown is critical to sustaining crop production potential in a field over a long period of time. And while it’s becoming more difficult because of increasing stalk strengths, the right equipment can help better manage them in the field. If you consistently encounter issues with strong stalks, adding an implement like a roller can help encourage optimize in-field breakdown.

“Some producers will attach a roller to the tractor or use a corn head with a stalk-stomper on it to help knock them down,” Elder said.

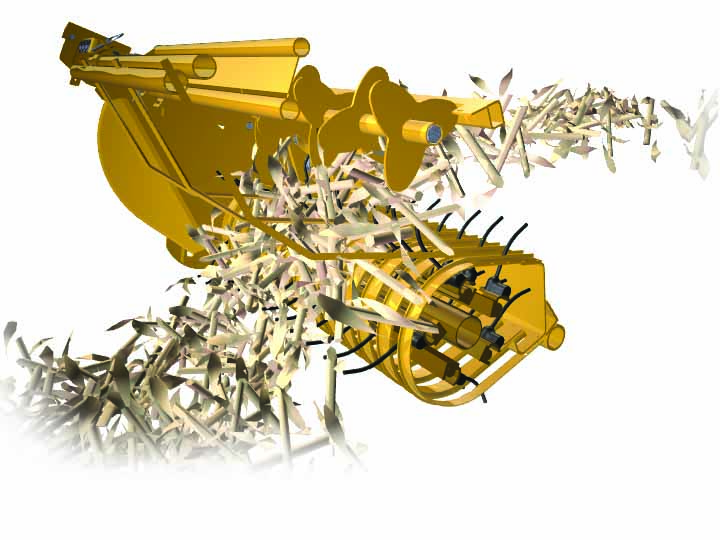

When baling rock-solid stalks — whether or not you’ve rolled or crimped them — there’s greater potential to inflict damage on balers and hay-making equipment, especially wear parts. That makes it important to bale cornstalks with the right equipment, specifically a baler with components that can help manage today’s stronger stalks. The Vermeer 605N Cornstalk Special baler was specifically designed to handle the tough conditions and crop that comes from cornstalks.

“The 605N Cornstalk Special helps with crushing and crimping the crop as it enters the baler. Rubber-mounted pickup teeth hold up in tough field environments,” Vrieze said.

Baling cornstalks that require tough components

Those teeth are part of the group of components that are most likely to incur damage from strong stalks while baling, and the 605N Cornstalk Special reflects the concentration on those parts that need to be tough to handle the heavy crop residue.

“The part of any baler that’s going to take the most abuse is the pickup. You’ve got to start with a good, strong and heavy pickup tube so you’re not changing pickup teeth in your baler before you even get started baling,” Elder said. “That’s why we offer the heaviest rubber-mounted teeth on the market.”

Verifying all the residue makes it inside the baler can be a challenge. With adjustable gauge wheels that help provide necessary ground clearance, the 605N Cornstalk Special also includes a powered windguard — an idea that originated with a Vermeer dealer — that helps move material from the pickup to the bale chamber more efficiently. In addition, an automatic greaser helps keep bearings and moving components free of dirt and dust, which are both common when baling high-volume materials like cornstalks.

“The powered windguard helps crimp the crop and helps material flow better,” Vrieze said. “The auto greaser contributes to the longevity of the machine. It’s not always about getting grease into bearings, but about pushing dirt and dust out. It’s putting grease into bearings every few bales.”

Finally, the 605N Cornstalk Special design helps keep wear parts like chains clean and free of debris, dust and dirt, contributing to the machine’s longevity.

“The powered windguard and other features make the capacity of this baler increase significantly compared to the standard 605N,” Vrieze said. “This cornstalk baler performs well in the field. When a producer needs baled cornstalks, having the right equipment is a big part of producing bales efficiently and economically.”

Thanks to modern genetics fueled by demand for corn that can stand stronger in the field up until harvest, today’s stalks are rock-solid compared to previous generations. While great for corn farmers, stronger stalks create challenges for cattle producers who use cornstalks as part of their feed rations. When combined with management strategies to help stalks break down better in the field, the right equipment — like the Vermeer 605N Cornstalk Special — can help producers overcome the challenge posed by today’s stronger cornstalks. Find out how, and learn more about the 605N Cornstalk Special by connecting with your local Vermeer dealer.

Information noted above was gathered from a third party who was advised his/her experience might be featured in marketing materials. This article contains third-party observations, advice or experiences that do not necessarily reflect the opinions of Vermeer Corporation, its affiliates or its dealers. Individual results may vary based on care and operation of machine and crop and field conditions, which may adversely affect performance.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region.

Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer, the Vermeer logo and Equipped to Do More are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries.

© 2019 Vermeer Corporation. All Rights Reserved.