Why It’s Valuable to Know Your Forage Tonnage

June 2018

Forage supplies were tight emerging from winter, leaving buyers facing high prices and low inventory and producers feeling the pressure to increase output and hay quality.

Now that the haying season has been underway for a few weeks, buyers and sellers look to work toward a more “normal” forage marketplace. There are many ways to both help maximize productivity and get a clear picture of how much you are producing or buying and selling. For the latter, a good strategy is buying and selling hay and baled cornstalks based on total weight. Typically done on a per-bale basis, buying baled feed by weight can help buyers and sellers know exactly what is being transacted, leading to a transparent agreement for both parties.

“If you are selling by the bale and not by weight, both parties are missing out,” said Larry Redmon, Texas A&M University Soil and Crop Sciences Extension Unit administrator and forage specialist. “I’ve seen people guess that a small round bale weighs 750 pounds (3401.2 kg) when it actually weighs 500 pounds (226.8 kg). The seller needs to be rewarded for what he is producing, and the buyer needs to know that he’s getting what he’s paying for.”

Benefits for the custom operator

There are benefits to knowing the weight of your bales on both the field level and when forage is marketed. Without a bale count as the measuring stick for productivity, a custom hay producer can focus on the steps he or she can take to maximize efficiency and tie pricing directly to tonnage, according to Vermeer Product Manager Josh Vrieze.

“Charging customers by the ton versus bales allows a custom operator to not worry about getting as many bales, but instead figure out how they can be most efficient in getting the same amount of tonnage put up,” Vrieze said.

In many cases, that change in focus results in a smaller number of bales that are often denser and yield a higher-quality, longer-lasting feedstock. With fewer bales, production costs decline. Less netwrap is necessary, and less time in the field is required, as you’re not stopping and ejecting bales as frequently, Vrieze said.

Knowing the weight of bales is especially important to the custom operator or producer when they’re fewer in number and higher in quality, Redmon added. “If an operator is putting up some really good hay and selling by the bale, he’s competing with the guys who put up poor-quality hay and he’s getting taken advantage of,” he added. “He needs to be rewarded for the quality of the hay he’s producing.”

Fairness between custom operator and landowner

If you’re a landowner or producer who’s working with a custom operator to put up your hay, there are similar benefits to basing output on total weight versus the number of bales.

“You know your custom hay operator is not ‘cheating you,’ by decreasing the density or size of the bales,” Vrieze said. “Knowing the total tonnage shows a field’s real output without the room for interpretation that comes with basing it on bale numbers. That’s especially valuable when hay supplies are tight and you’re working to maximize the value of your forage crop, whether it’s cornstalks or hay.”

Just as it benefits the custom operator, accounting for forage output by tonnage versus bale number often leads to efficiencies in the field that can reduce costs to the landowner. By focusing on overall tonnage, it’s easier for the producer or operator to justify increasing bale density and weight, and that shift in focus typically yields smaller bale numbers. This has long-lasting positive implications for the producer feeding that forage throughout the year.

“Fewer bales by the same amount of tonnage helps minimize storage needs and handling requirements, since you’re not moving as many bales,” Vrieze said. “You also don’t have to feed as many bales during the year.”

There are also feeding benefits beyond simply the smaller number of bales, ones that stretch well beyond feed bunk or ring.

“We can have two bales that are equal in size and look identical, but if one is six percent protein and one is 12 percent, I’m going to have to buy more supplements for that lower-protein bale,” Redmon said. “Or, we’ll wind up with calves with poor body scores and ones that are reluctant to breed back later.”

Benefits of baling your own

If you’re putting up your own forage, there are broader management benefits to account for your production on a tonnage basis versus the number of bales. Knowing exactly how many tons of forage you produce fits much more easily into year-round feed management. And, if you know how many tons you’re producing, you can more clearly see where you may have deficiencies that can be corrected agronomically during the growing season.

“Instead of saying you have 200 bales for the year, you can say you have 300,000 pounds, or 150 tons (136 MT) of feed for the year,” Vrieze said. “This allows you to more effectively plan your feed supply for the year, and it tells you what fields are producing more per acre than other fields. If your tonnage total shows you one field is not producing what it should, you can explore ways to better manage pests or soil fertility to improve production.”

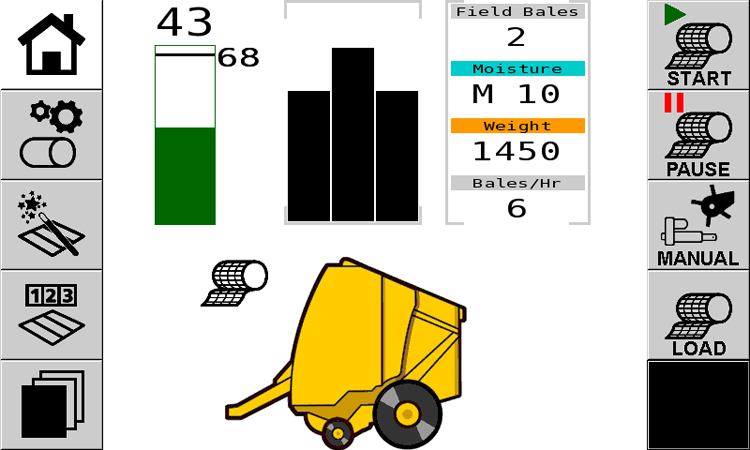

One hay weight solution

So, what’s the best way to weigh hay straight out of the field? The Vermeer 604N and 605N balers offer an optional real-time bale weight data kit with an onboard scale, allowing the operator to see immediately how much tonnage a field is producing during baling. That data is also recorded in a spreadsheet format allowing for broader views of forage performance, a useful tool in making management decisions.

“The scale kit allows producers to weigh their bales and get that data via their monitor/control system,” Vrieze said. “Not only can an operator see real-time data but he can also export that data to a .csv/excel file via E-Link Pro. It’s a helpful tool to have both during and after the growing season.”

Vermeer Corporation reserves the right to make changes in product engineering, design and specifications; add improvements; or discontinue manufacturing or distribution at any time without notice or obligation.

Vermeer, the Vermeer logo and Equipped to Do More are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries

© 2018 Vermeer Corporation. All Rights Reserved.