Wider Swaths Lead to Better Hay & Haylage

April 2015

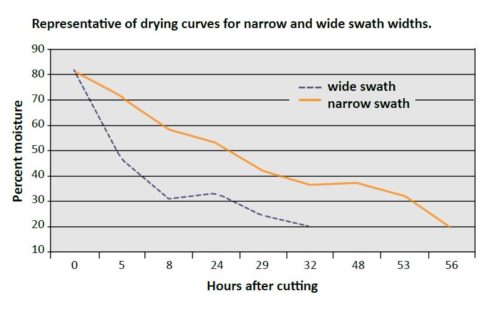

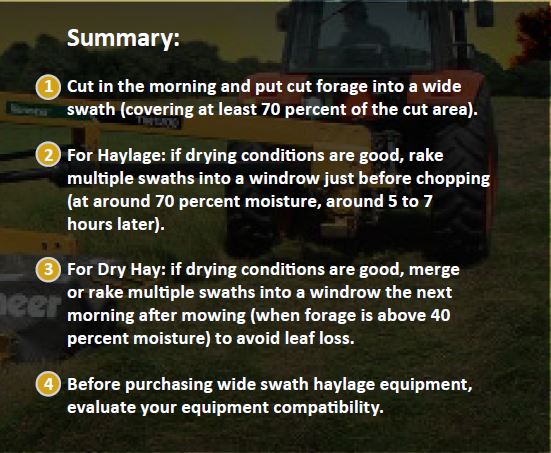

The idea is pretty simple. Instead of putting freshly cut forage immediately into windrows for ease of handling, why not leave it in much wider swaths and let Mother Nature (air and sunlight) speed up dry down through the increased exposure.

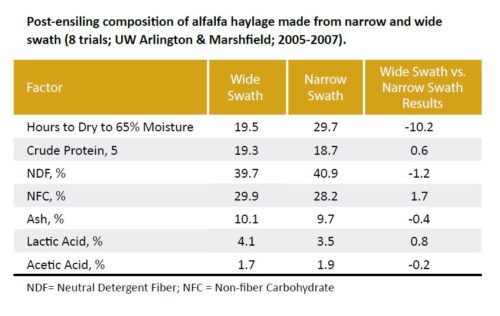

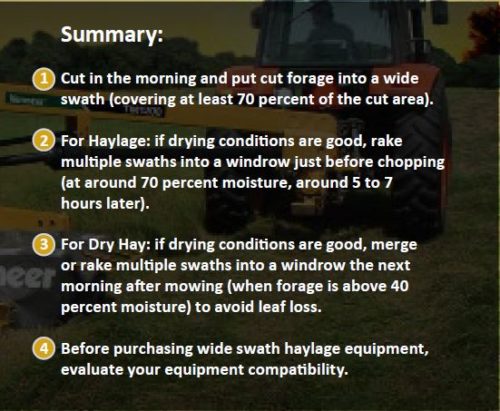

This management practice was not very common until a series of independent research studies conducted by Cornell University and University of Wisconsin Ag Extension Centers. Both uncovered some very impressive results. And, many growers have now embraced this system to harvest their high-moisture forage; cutting in the morning, harvesting six-to-seven hours later and ensiling before sundown.

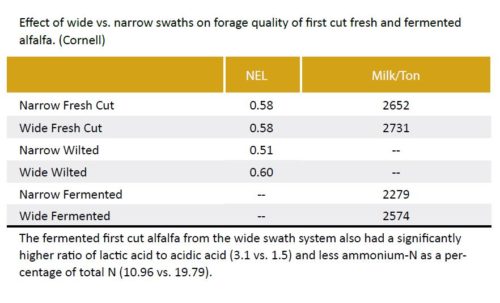

Changes and results in forage production have been significant. Shorter wilting periods. Lower respiration losses. Higher sugar/starch content (especially first-cut forages). Better quality forage. More digestible energy. Improved fermentation. And, of course, less chance of rain damage. And, for dairy farmers? Incremental improvements in milk production have been huge – with increases reported in the neighborhood of 300 lbs. in milk production (per ton of haylage fed).

“Actually, we used to cut hay into wide swaths years ago before conditioners,” says Dan Undersander, a renowned research forage agronomist at University of Wisconsin Extension Services. “But, when mowers and conditioners got bigger, the swaths and windrows we formed –percentage-wise – became relatively smaller and more dense.”

“Today, as we pay more attention to the biology and physics of properly drying forage, we’re seeing how rapidly lowering moisture levels (by about 15 percent) reduces the loss of starches and sugars and preserves more total digestible nutrients (TDN). And, the single most important factor behind this improvement is the wider swath. We’re also seeing where conditioners have little impact at this initial drying stage, because most of the early moisture loss happens from the leaf. As a result, we’re doing a much better job of maximizing quality and TDN in our harvested forages.”

What about the advantages of conditioning?

“Our haylage customers are seeing the same thing,” says Josh Vrieze, Dairy Product Manager at Vermeer. “Wider swaths definitely speed up dry down, which even allows them to forego conditioning.”

“In fact, studies show conditioning can actually slow down wilting speed at higher haylage moisture levels. So, if you’re harvesting high moisture forage, this popular practice is definitely worth consideration.”

What about dry hay?

“Obviously, if you’re harvesting dry hay, conditioning is crucial because dry down needs to continue to a 15 to 20 percent moisture level. Strategies for wilting silage are very different compared to dry hay production. Here, conditioning the stems is extremely important. However, the practice of forming wider swaths, (at a higher percent relative to the cutting width) has advantages when harvesting both high-moisture or dry hay.”

“If you’re purchasing a new mower or mower conditioner, the width of your swath, relative to the cutting width, becomes a very important factor. Most mower-conditioners (especially those wider than 9 feet) aren’t able to adjust to an 80 to 90 percent width swath. So, pay attention. Swath width percentages can range anywhere from 28 to 87 percent. The wider, the better – preferably, you want it to be in that 70+ percentile,” Vrieze added.

When grasses are cut they should generally be formed in wide swaths, especially if no stems are present. Otherwise, the forage will settle together, dry very slowly and be difficult to separate for faster drying.

To maximize results, Undersander suggests raking when haylage is around 70 percent moisture. Also, keep in mind, this system needs to be planned out. You do not want to cut more acres than you can harvest before the higher moisture forage gets too dry for ensiling, in case of unfavorable weather conditions.

To minimize leaf loss in dry hay alfalfa, he recommends raking or merging the swaths when moisture levels are above 40 percent (above 25 percent in grasses). Generally, raking about 24 hours after mowing, is a good practice when making hay. Raking boosts the drying rate again – on the day the hay is raked – as the unexposed material is turned. But after that, the drying rate slows considerably, and is impacted more by sunlight and humidity.

Concerned about driving over wide swaths?

Cornell research indicates that, in wide swath situations, driving over cut swaths with the tractor does not significantly affect drying. However, it could lead to soil contamination and adversely affects fermentation, particularly in wet field conditions. Driving over a wide swath is less damaging than making a windrow to avoid driving on the hay.