Plastic wrap for dry hay sustains quality

January 2021

Adam Wise is the sixth generation of his family to farm near Punxsutawney, Pennsylvania. The farm, set in the lush rolling hills of west-central Pennsylvania, has been in the family since 1837, a testament to how his family has integrated new farming practices to keep it viable and productive over time.

When it comes to the family’s forage operations, Wise has proven the benefit of another new practice — wrapping dry hay — to continue the long heritage of raising high-quality beef cattle and forage crops.

Wrapping dry hay has made a big difference on the farm for Wise, and integrating it has enabled him to be more resourceful with his hay output and better manage his labor and hay tools without considerable investment.

Why make the switch to wrapping dry hay?

The practice of wrapping round dry-hay bales was a solution to two immediate challenges Wise and his family experienced with the traditional practice of chopping hay, haylage and silage as feed for their growing herd of 250 beef cattle, show steers and heifers. First, it enabled them to better protect the hay and sustain its quality over longer periods of time when stored outdoors. And secondly, it streamlined labor resources and time by using the same process and hay tools for both wet and dry hay. On top of that, it made more financial sense for the Wise family.

“We started by wrapping our wet hay and saw how much less hay we had going to waste. So now, we wrap it all — wet and dry hay — unless we know we’re going to feed or use it within a month. It just works well for us right now,” Wise said, adding they often use most of their bales within a year of production. “We realized that with our silage equipment — a pull-type chopper and a couple of wagons — we could make hay faster with a round baler than we could chopping it. Some producers might hear that and say there’s no way it would work. But for us, the number of acres we have and the cost to get a self-propelled chopper and update our silage equipment is considerable, so we started making all bales.”

In 2020, the Wise family baled 1,800 silage, alfalfa and oat hay bales — 75% of which were baled dry — that he and his family use to feed and bed their herd. Every one of those dry bales made by his Vermeer 605N baler, was wrapped with plastic stretch-film.

The Wise family is now able to maximize their time and resources by producing both wet and dry round bales with a standard process. Wise, his parents and one employee are able to take advantage of optimal times to make hay and get bales wrapped before inclement weather and rainfall can erode forage quality.

“A lot of the time, we have one person mowing, one person on the rake and a third on the baler. Then, when the rake operator is done, he goes and starts hauling bales right away,” Wise said. “We haul all our bales to a central location by our in-line bale wrapper. A lot of times, we’ll mow hay during the day and do our baling and wrapping that following night. We try to wrap it as soon as we make it unless we know we’re going to have a wide time window in the next few days. We like to let it sit and let the bale sweat for a couple of days if we can, but if we can’t, we’ll wrap as soon as we can to prevent bales from getting rained on.”

The nuts and bolts of wrapping hay

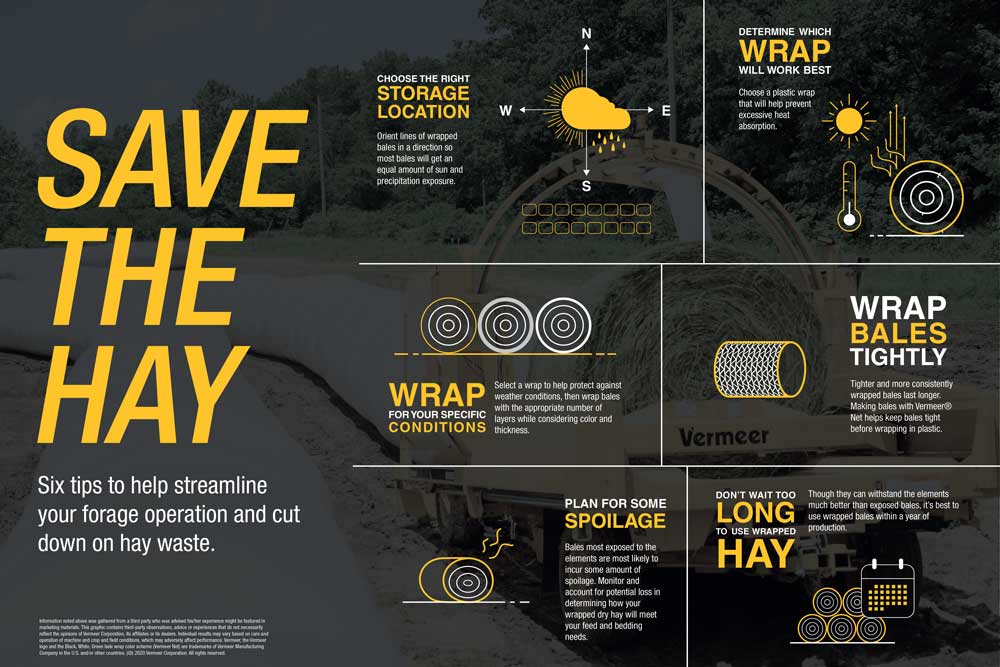

Wise doesn’t have adequate barn space to store all the farm’s forage output year-round, hence the initial interest in wrapping all his farm’s bales. It does come at a cost; he said the family purchases plastic wrap every year, and it typically costs around $4 to $4.50 per bale. Each bale is evenly and tightly wrapped in eight partially overlapped layers. Bales are typically stored in rows of 65 to 70 in an east-to-west orientation. Given most weather systems arrive to the area fairly predictably from the west, this helps promote more consistency in the crop. It’s impossible to prevent all hay loss from spoilage, but wrapping first with Vermeer® Net, then wrapping in bale wrap film, helps cut down on hay loss and prevents bleaching damage from the sun. He’s yet to calculate the total hay savings, but Wise said the quality and quantity improvements are easily noticed.

“I think it’s worth the cost. Wrapping our bales cuts down on hay waste considerably. I don’t have a number to say how much, but I know the calves eat it all. When we wrap dry hay tight like silage, it keeps better. Sure, we have one or two end bales that have a little spoilage on the outside layers, but nothing like we used to. Once you start getting two or three bales deep into a line. It’s almost like the day you put it there,” Wise said.

Once hay is wrapped and stored in white bale plastic wrap (Wise said they’ve used black plastic wrap before, but it has a tendency to promote more spoilage due to heat absorption), it can last well over a year. Using Vermeer Net prior to wrapping in plastic helps make bales more consistent and prevents air pockets that can breed spoilage when stored. Once the hay’s ready for use, he simply cuts the film to remove it prior to setting in a feed ring.

“We try to buy the best plastic wrap we can get,” Wise said. “When a bale is wrapped well, the hay will still have a nice greenish color to it long after it’s been wrapped. There’s no discoloration that indicates excessive heating or lost quality.”

Moving forward, Wise said he’ll likely bale both his wet forage and dry hay in both Vermeer Net and plastic wrap for the foreseeable future.

Information noted above was gathered from a third party who was advised his/her experience might be featured in marketing materials. This article contains third-party observations, advice or experiences that do not necessarily reflect the opinions of Vermeer Corporation, its affiliates or its dealers. Individual results may vary based on care and operation of machine and crop and field conditions, which may adversely affect performance. Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications. Vermeer, the Vermeer logo and the Black, White, Green bale wrap color scheme are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. © 2021 Vermeer Corporation. All Rights Reserved.