Expert advice on simplifying your rake selection

May 2025

When it comes time to add new hay equipment to your fleet or upgrade to a new model, it’s important to remember that there’s not a one-size-fits-all solution. Instead, you should consider many factors during the equipment-buying process.

Rakes tend to be a lower investment on many operations, but that doesn’t mean it’s an unimportant decision. The type of rake used can be influential on the value and quality of the crops you produce. When adding a rake, work with industry experts and your local agriculture equipment dealer to review the various styles and models available that best align with your operation’s unique needs.

Shawn Wang, a product manager, and Bart Elder, a regional manager at Vermeer, both bring extensive experience in the forage equipment industry and deep knowledge of hay equipment design.

Elder suggests asking yourself a few questions before the hay rake buying process:

- How many acres do you plan to rake?

- What is the planned usage of the hay?

- What is the horsepower of the tractor you plan to use with the rake?

- What types of crops are you planning to handle?

Once you have answered those questions, you can narrow what styles or models might be well-suited for your operation.

Types of hay rakes

There are three types of machines offered by Vermeer to help you rake hay: wheel rakes, basket rakes and rotary rakes. Each machine and model will be best suited for different crops, operations and tractors, so you will want to inventory your wants and needs with your new rake before you begin shopping for equipment. While all three have various features, adjustments and technology — your local Vermeer dealer can help you find the best fit for your farm or ranch.

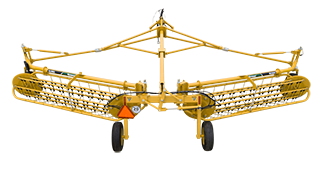

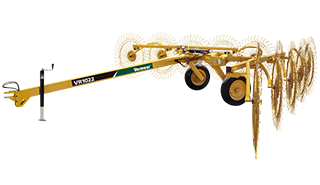

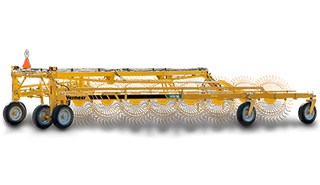

Wheel rakes

Finger wheel rakes are a popular option when raking dry hay or cornstalks but are versatile enough to work on most crop types.

Hay producers understand the importance of timing when harvesting, and fast and efficient raking is crucial. Wheel rakes excel when navigating over rough terrain while still being able to rake at a higher rate of speed. They are also simple to use and at an economical price point, making them a good option for newer producers in the hay and forage industry or those who need a machine that can handle additional wear and tear in the field.

Before purchasing a rake, it’s key to consider the potential tradeoffs you may encounter. When it comes to wheel rakes, those tradeoffs are limited performance in wet, heavy crops for baleage and decreased hay quality — which is important to consider if you plan to use the crop for dairy cattle or horses. As a ground-driven rake, it can introduce more ash content and reduce the quality of the crop.

If you are considering a compact and maneuverable wheel rake for your operation, consider the VR820, VR1022 and VR1224 carted wheel rakes. For farmers and ranchers tackling a large number of acres, the higher capacity VRB and VR series bi-fold wheels rakes could be a valuable asset to your operation. Due to a unique hydraulic suspension system, the VR1428 and VR2040 high-capacity rakes are especially effective in cornstalks or when working over rough terrains.

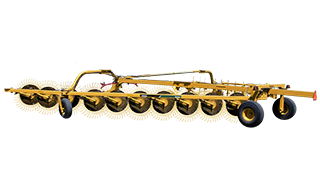

Basket rakes

Many farmers and ranchers are likely familiar with hydraulic basket rakes — also known as parallel bar rakes or twin rakes — for their durability and straightforward maintenance. Producers who want to minimize time working on equipment and spend more time in the field can rely on basket rakes, which have heavy-duty components and a design that simplifies maintenance.

Producers who work with a variety of crops find basket rakes an ideal option as they can handle both wet and dry forages. In the field, basket rakes produce highly consistent, box-shaped windrows. The hydraulic drive system powers the machine, introducing less ash into the windrow and resulting in higher-quality forage, which is crucial for feeding dairy cattle or horses.

If your operation regularly resells or trades equipment, it’s important to note that basket rakes have a reputation for machine longevity and retaining their value well. Basket rakes can serve most operators for many years depending on maintenance upkeep and acres covered.

Wang said, “Basket rakes durability combined with their simple design compared to some rake models makes maintenance exceedingly straightforward for operators.” Regular inspections of bar teeth are essential to ensure proper functionality, and replacement may be necessary over time.

When comparing rake models, hydraulic basket rakes are typically at a higher price point than wheel rakes of similar raking width. The machine’s initial price may be intimidating — however, it’s important to consider its durability and the future trade or resale potential.

For producers seeking a durable machine built to last, produces high-quality forage and promotes straightforward maintenance — models like the Vermeer R2300 and R2800 twin rake could serve your operation well.

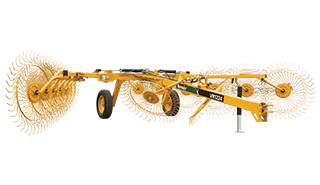

Rotary Rakes

Rotary rakes, originally popular in European markets, are gaining popularity in the US and Canada — especially for producers tackling a variety of crops. Vermeer has recently announced two new additions to the rotary rake lineup: the RR140 at 15.1 ft (4.6 m) wide and the RR270c at 27 ft (8.3 m) wide. As a long-standing leader in the hay rake market, Vermeer has developed these new models to give producers more options for equipment that can help maintain nutritional quality while also reducing ash content.

Equipped with a mechanical drive system, rotary rakes efficiently handle both wet and dry hay while minimizing ground contact to reduce contamination. In the field, rotary rakes deliver highly consistent, light and fluffy dome-shaped windrows delivered from the center or side. A specialized lift, carry and drop design on Vermeer rotary rakes gently lift the crop to get even more airflow throughout the window.

Servicing rotary rakes can be tedious for some producers, as they have more moving parts, and a complex design compared to other rake styles. With rotary rakes having some specialized parts, they may require a certified technician to make repairs.

For producers who complete their own maintenance and repairs, Vermeer rotary rakes were designed for ease of maintenance throughout the machine. Some components that enable simplified maintenance on Vermeer rotary rakes are: Modular rotor featuring separately removable spring tine arm pairs with each tine arm being secured with only three bolts, helping to streamline maintenance and adjust quicker than ever.

Vermeer rotary rakes were built for maximized durability, even in rough or bumpy fields. A patented walking tandem axle featured on Vermeer rotary rakes enables smoother tracking throughout fields. With 420-cm (165-in) cam tracks that do not require oil bath lubrication, these rakes can better hold up in challenging conditions as well as reduce time spent checking oil, changing oil or fixing leaks.

Producers who want to work quickly, have challenging terrain or a significant number of acres to tackle may find rotary rakes to be a good fit.

For farmers or ranchers who strive to produce a high-quality forage and want to keep horsepower requirements low, rotary rakes like the Vermeer RR140 rotary rakes could be a great asset on a hay and forage operation.

When selecting a rake be sure to consider field conditions, forage type, maintenance capabilities and budget. If you are unsure on which model would be a good fit, seeking advice from an industry expert can help make an informed decision that meets operational requirements. If you have more questions about what equipment is right for you, your local Vermeer dealer can help.

Vermeer Corporation reserves the right to make changes in product engineering, design and specifications; add improvements; or discontinue manufacturing or distribution at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. © 2025 Vermeer Corporation. All Rights Reserved.