Maximize your operation: cattle feed mixers vs. feed wagons

November 2022

Forage waste can be costly. When margins are already tight, you want to find ways to maximize your herd’s nutrition and minimize waste. A vertical mixer or feed wagon may be the answer for you. With multiple sizes available, the Vermeer lineup of vertical mixers and feed wagons gives you the option to mix or blend all ration ingredients like dry hay, silage, grain and ethanol coproducts at once. Let’s take a look at cattle feed mixers vs. feed wagons.

What are the benefits of a Vermeer vertical mixer?

If you’re like most cattle producers, feed costs are probably your biggest expense. Rather than free-choice feeding, paying close attention to the type and number of ingredients you’re feeding your cattle — and how you’re distributing them to your herd — can make a big difference in your overall feed costs.

A vertical mixer can help make feeding more efficient. It can help you optimize your total mixed ration (TMR) because it processes and delivers the right mixture of roughage, protein and energy for your herd without increasing your labor requirements. You can optimize the quality of your rations and change feed ingredients based on feed availability and the nutritional needs of your herd at any given time. With a mixer, you can also deliver a consistent complete ration each feeding, which can help prevent waste.

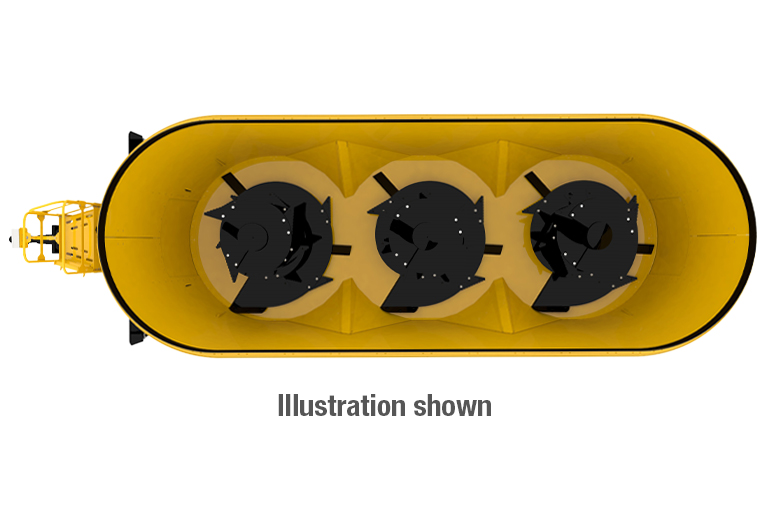

The Vermeer line of vertical mixers features a proven tub and screw design, with single-screw, twin-screw and triple-screw options. Available in a range of capacities from 350 cubic feet to 1,690 cubic feet (9.9 m3 to 47.9 m3), these vertical mixers can handle a wide assortment of feedstuffs.

What’s the difference between single-, and twin- or triple-screw mixers?

All Vermeer mixers have durable components for long-lasting performance. These components include two bi-pulse legs and one to three screws that work together with the legs to create three points of contact with the tub floor for efficient cleanout.

The differences between Vermeer single- and multi-screw mixers are related to their capacities. Mixers smaller than 600 cu ft (METRIC) feature one screw, whereas anything above 600 ft3 (17 m3). has two or more screws in order to keep the loading height as low as possible for different operations.

Vermeer twin- and triple-screw vertical mixers feature overlapping screws and offset baffles on the tub wall that help achieve a consistent, thorough mix. Feedstuffs are completely cleared from the front and back of the tub because the tub and screws are designed to move the material between the screws in a clockwise motion for maximized consistency in the ration.

What are the benefits of a Vermeer feed wagon?

Some producers find that Vermeer feed wagons are better option for feeding their herds. These wagons are efficient to use and maintain. Somewhat similar to a vertical mixer, feed wagons give you the flexibility to blend rations with various ingredients and effectively and consistently distribute them. They can both help control the feeding of valuable ingredients and animal feed intake, helping you more efficiently manage your input costs.

What’s the differences between Vermeer BF- and HF-series feed wagons?

BF- and HF-series feed wagons have a lot in common. Both offer a certain amount of blending of feedstuffs as they progress through the machine. However, there are a few notable differences, especially when it comes to the ability to handle roughages.

| BF-SERIES FEED WAGONS | HF-SERIES FEED WAGONS |

| Ability to handle up to 20% roughages | Ability to handle up to 100% roughages |

| Simple and reliable mechanical drive from tractor PTO | Hydraulic drive for low maintenance |

| Option of auger or slat-and-chain discharge | Slat-and-chain discharge with folding extension |

| Elevator chain blending mechanism | Beaters blending mechanism |

| Smaller wagon sizes | Larger wagon sizes |

How do feed wagons work?

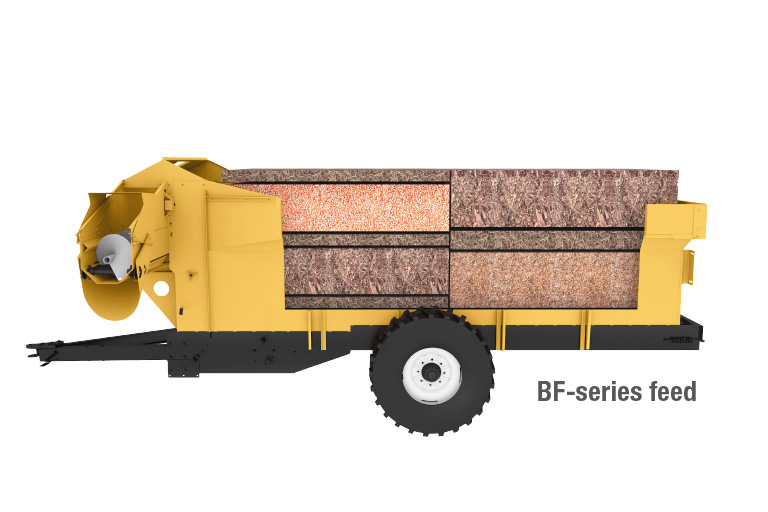

While vertical mixers mix ingredients for you, the key to blending ingredients in a feed wagon is layering them properly. The easiest way to think about loading these machines is to compare it to making a sandwich. You’ll load in layers to allow for even distribution as feedstuffs move on the elevator chain or through the beaters during discharge and distribution. The amount of each feedstuff you use will depend on what series of Vermeer feed wagon you’re using.

If you’re using all forages and commodities, alternate the loading order as seen on the left-hand side of both wagons below.

If using a combination of hay, silage and grains, operators should load grain on the bottom, then hay, then silage on top as seen on the right-hand side of both wagons below.

Choosing a cattle feed mixer vs. feed wagon for your needs

Which feeding solution is a better fit for your operation’s needs? When choosing the right cattle feed mixer or feed wagon, be sure to talk to your local Vermeer dealer. They can help you find an efficient solution for feeding your herd.