Vertical Feed Mixer Maintenance Checklist

December 2023

Labor shortages, high input costs and other on-farm challenges call for maximized efficiency and minimal waste. For this reason, many cattle producers have embraced lean farm management and added a Vermeer vertical feed mixer to their equipment shed.

A vertical feed mixer is not a one-size-fits-all solution, but it can help minimize waste and enhance feeding efficiency. If that’s your goal, it might be time to find the right vertical mixer for your operation.

After all, data shows free-choice feeding can waste up to nine pounds of feed per head per day. Over time, that daily waste can add up to a substantial cost. A vertical feed mixer can help you avoid it, but you’ll want to protect your investment with routine maintenance.

Looking for vertical mixer maintenance tips? Vermeer Territory Sales Manager Jordan Schuler has some advice — but also notes local Vermeer dealerships are happy to conduct regular inspections and maintenance to help keep machines running their best.

From the bottom up

Just like with a car, vertical feed mixer maintenance can start by checking your tire pressure and lug nut tightness. You can find the recommended pressure and torque specs in your operator’s manual.

Next, check the bolts holding the conveyor slats and the conveyor chain tension.

“Line a slat up with the center of the discharge door and ensure that the slat lightly touches the bottom of the tub floor when lifted,” Schuler explained. “If the slat cannot be lifted to the floor or touches it with very little effort, refer to your operator’s manual and loosen or tighten as needed.

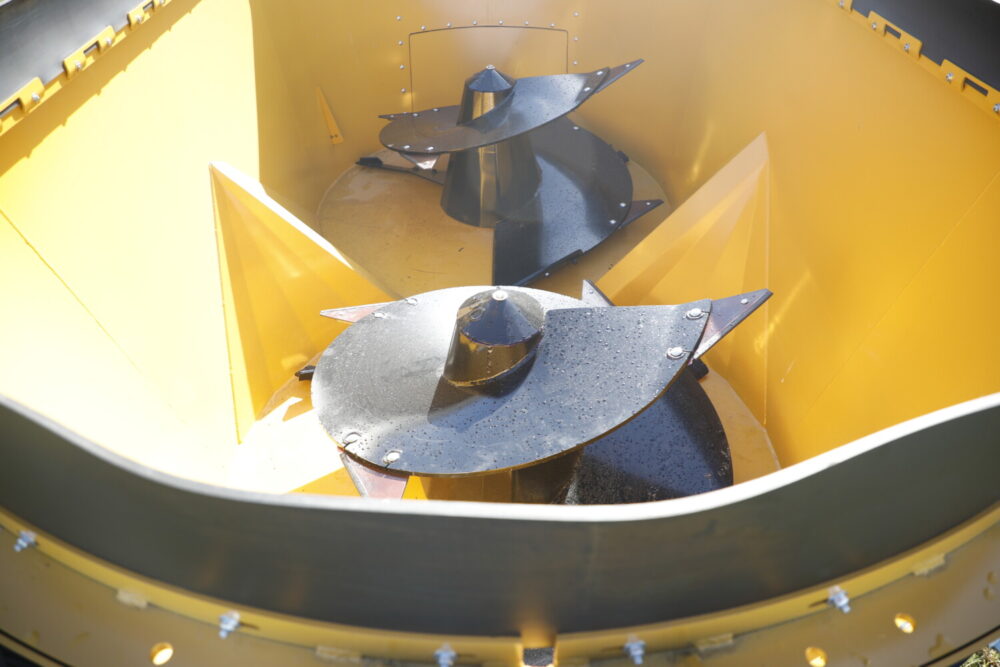

In the tub

Inside the tub, look at knife condition and blade edge to check for wear. Schuler said it might be time to change the knives if they’re visibly worn or if forages aren’t being processed to the desired length.

To switch out knives, start by making sure the engine speed is on low, the PTO is disconnected and the parking brake is engaged. Next, to lower the conveyor extension, open the discharge door, move hydraulics to neutral and shut off the tractor. Once the discharge door handle is in the locked position, enter through the discharge door to cover the knife blades before changing them.

Remove the flange lock nuts and carriage bolts, detach the knives and blade backing plate from screw, and keep the fastening hardware for later. Attach the new knives and backing plates to the screw and unlock the discharge door handle when finished.

While the machine is off, Schuler said it is also a good time to power on the scale to check weigh bars and the scale system.

“Put a tractor weight or other item with a known weight on the conveyor and confirm the weight displayed closely matches the item and the weight remains fairly constant,” he explained.

Oil change

Schuler reminds producers they should complete other routine maintenance like checking the oil level and re-packing grease in the mixer’s hubs, as well.

“This is also the time to change the planetary gearbox oil and change the 2-speed gearbox oil, if applicable,” Schuler said.

Before removing the drain plug, he said to run the mixer for 20 minutes to warm it up before following the machine’s shutdown procedure. Once all the oil is drained, reinstall the plug and remove the breather plug before filling it with oil. Put the breather plug back before running the machine.

Schuler tells vertical feed mixer owners to finish up maintenance by greasing the PTO and all the grease points on the mixer. These points can be found on the machine’s grease chart in the operator’s manual.

“Remember, performing checks and maintenance now is a great way to deliver peace of mind around machine performance when the bunks are empty,” he said.

Need some help with routine maintenance? Your local Vermeer dealer can help ensure your equipment is in tip-top shape. If you haven’t purchased a vertical feed mixer, consider adding one to your equipment lineup to combat today’s labor shortages, high input costs and other on-farm challenges where you need maximum efficiency and minimum waste.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation.

Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region.

Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries.

© 2023 Vermeer Corporation. All Rights Reserved.