What the Pros Use

June 2015

Every year during the fall, combines can be seen finishing harvest in fields across the country. But even after the grain’s been harvested and fields are empty, the work’s not done. For two custom operators in Northwest Iowa, work is just beginning.

Along with his father, brother-in-law, neighbor and son, 33-year-old Jeremy Homan runs a custom baling operation out of Remsen, Iowa. Throughout the year, the family puts up alfalfa, grass hay and straw, raises corn and soybeans and also finishes 100 head of Jersey steers. However, in the fall, Homan’s main focus is cornstalk baling.

Putting up 8,000 bales of cornstalks a year isn’t all Homan does. His baling business operates after hours when he’s finished working his daytime job.

“I work a fulltime job as an ag lender,” Homan said. “Sometimes I rely on taking time off in order to put up stalks when time is critical, but a lot of my work gets done from the hours of five in the afternoon and running into the early hours of the morning.”

Homan depends on technology and reliable equipment to help him get baling done faster with better results.

“It’s all about efficiency,” Homan said. “Especially from a custom business standpoint – we’re trying to get the most bales per hour. We need to be timely for our customers because they’re depending on us to get the job done. They need cornstalk bales for bedding and feeding their cattle. We have a small window of opportunity in the fall, and we need to be efficient.”

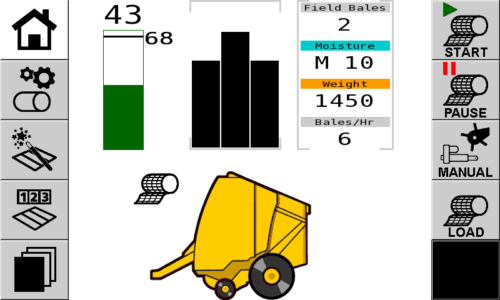

In order to help operators like Homan be the most productive they can be, Vermeer has added several updates to the E-Link Pro display – a user-friendly color touchscreen that offers enhanced visibility to bale weight, moisture readings and more.

Launched two years ago on the Vermeer 504 PRO baler, the E-Link Pro display now comes standard on all 2015 models of the Vermeer 604N/605N balers and 604N/605N Cornstalk Special balers. Homan has been using the display for over a year and currently runs it on both of his Vermeer 605 Super M Cornstalk Special balers. Homan said the feature he appreciates most about the display is its ability to keep track of how many bales he’s getting off a field.

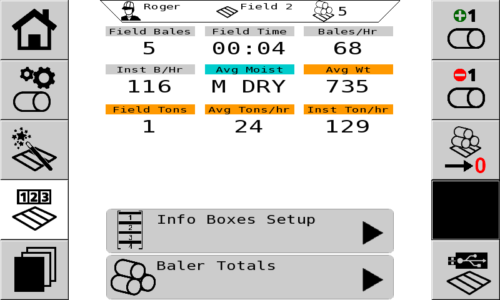

“The most useful feature for me is the bales per hour reading,” Homan said. “It helps us forecast what we’re going to be able to accomplish throughout that day. And it helps make adjustments with other equipment, whether it’s adjusting a rake or windrow size or the type of field we’re in. Just being able to understand where you’re at for bales per hour and how different field conditions affect the productivity you have with the machine is useful.”

Any operator will agree there’s a lot to keep track of when baling. Homan said having more accurate readings of everything that’s going on helps him make better decisions while he’s in the field.

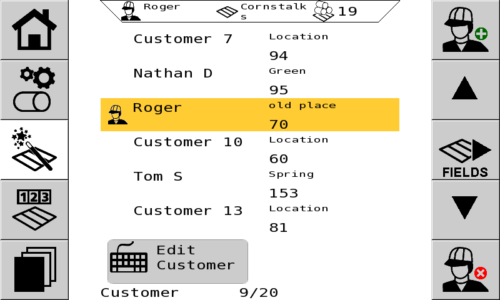

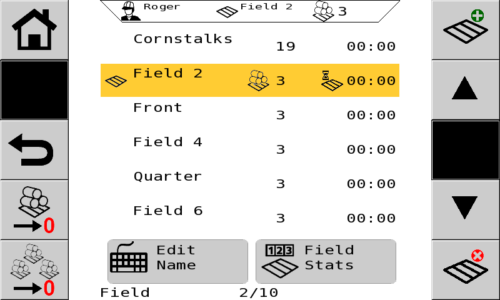

“The display has a lot of information to utilize that helps us monitor bales per hour, different customers, fields within those customers, and it’s been easy to monitor current moisture, average moisture and weight as well,” Homan said. “There are times where moisture doesn’t give you the best indication of what the crop’s doing, and there are times where weight doesn’t give you the best indication. The combination of both allows you to make good decisions.”

Homan is not the only operator who appreciates the information output of the E-Link Pro. 56-year-old Loren Weier of Linn Grove, Iowa agrees.

“The thing I like more on it than anything,” Weier said, “is that I can put my customer’s name and field locations in and it will keep track of number of bales baled, baling times per field, average moisture per bale, total tonnage off the field and average tonnage per hour. It gives you a real good record keeping option. When you get done and send your customer an invoice you can put all the information on their receipt – what the moisture was, what their average weight was per bale, and it gives them a real good guideline to see what their crop conditions are.”

Weier runs two Vermeer 605 Super M Cornstalk Special balers and has recently added the Vermeer 605N Cornstalk Special baler to his fleet, which helps his team of seven workers keep up with their baling business.

“My dad and I have a custom baling operation together,” Weier said. “When we started the business 40 years ago and put up 1,500-2,000 bales, we thought we had a good year. Now we do between 14,000 and 15,000 bales per year.”

“The majority of those bales are cornstalks,” Weier continued. “Our biggest cornstalk customer we work for cuts his own stalks. We rake them together and bale them and then he moves them off the field himself.”

To keep track of information on all the bales for each of his customers, Weier relies on technology in the E-Link Pro display. He said that providing his customers with this much information helps them with their manure management plans.

“Big cattle producers are finding that with knowing approximately how much tonnage they’re taking off the field, they can give that number to their agronomist and then figure out how much manure they can put back on their field,” Weier said. “If they take x-amount of [cornstalks] off per acre, they can actually add a little more tonnage of manure to replace what was taken off. It works out good that way, and it’s better for the Department of Natural Resources (DNR) because they have a better record of manure management plans when they can see what’s been taken off and put back on.”

Sam Harper, farm manager and agronomist for Pro-Crop Farm Management and Consulting in Royal, Iowa, works with cattle producers to develop manure management plans specific to their operation.

“Every large livestock facility falls under the realm of the DNR,” Harper said. “The DNR uses manure management plans to regulate these facilities. [Producers] need to try and maintain their records for the plans to help protect the environment and themselves if they have an incident or the DNR conducts an audit. It’s a necessary part of business.”

“I help consult with people to make sure they know what they’re doing with the manure,” Harper continued. “What I focus on is how much manure they’re putting on and how frequently they can put it on. For a corn on corn situation, taking the bales off is part of residue management. When you have all that biomass from harvesting corn, the soil doesn’t warm up as easily in the spring and there’s plant tissue that may have fungus. By removing it, that allows those problems to be minimized. So by tracking the amount of tons of bales we’re taking off, we know how many nutrients we’re using and how many nutrients we’re putting back on because of the manure. We’re looking for ways to apply that manure where it makes environmental and economic sense.”

According to Weier, increasing the amount of manure producers are putting onto the field equates to lower fertilizer costs. Harper agrees, but also said there are other benefits involved.

“When a producer or anyone has access to manure, they should consider using it for fertilization,” Harper said. “While the nutrient analysis for manure may be variable, producers can still predict how many nutrients they are applying. If additional commercial fertilizer is needed, then it can be applied. Manure can sometimes be compared in price to commercial fertilizer, but if you own the manure it is the best value fertilizer you can get. Manure has been proven to help build soil tilth. The mineralization qualities are also similar to the actions that occur when using cover crops. These reasons make manure a solid agronomic, environmental and economic option for maintaining fertility on farms.”

In addition to the environmental benefits of collecting data from the E-Link Pro display, Weier said he’s seen a positive impact on his own business.

“For me as the operator, it’s good because I can keep track of bales per hour, how many hours it’s taking to do a field,” Weier said. “That way I can figure my fuel cost in along with what it’s taking for baling so I can figure my efficiencies out, where I can improve and what I can do to make things work better.”

“It also saves time and makes keeping track of invoices easier,” Weier continued. “Instead of writing things down on a calendar, keeping track of dates and making sure no papers get lost, now I can just take my USB drive, plug it in, download onto it and take it home. I can transfer my information from my E-Link Pro to QuickBooksTM and take care of all the invoicing I need to do. It works real well.”

For Weier, it’s all about getting the job done and moving on to the next one until the season’s over. Of course the work never stops, but it does slow down, and Weier said he’s looking forward to taking time off to go fishing with his son.

Homan also enjoys spending time with family whether that be watching his kids’ sporting events or coaching both his sons’ basketball teams. What he enjoys most, though, is spending time together on the farm.

“Both of my sons show interest and passion in agriculture,” Homan said. “They really enjoy going to the farm, being around livestock, having something to do. It seems like every one of the kids goes through a stage where they’re out wandering around and we find them eye level with a cow pushing up feed. All our kids have an interest in agriculture and farming. I like that because I think more people need a sense of appreciation for agriculture and the responsibility that comes with.”

For more information on DNR manure management and crop residue plans, visit: