Equipment Considerations When Baling Corn Stover

October 2020

Baling cornstalks, or corn stover, is a dirty business. Because of that, you need to consider many factors when determining your equipment needs for the job. Durability is key, but you should keep several other items in mind to help keep things running smoothly and efficiently when baling cornstalks or stover.

Consider baler durability when putting up cornstalk bales

Perhaps the most important factor when baling cornstalks or corn stover is the overall durability of your baler and other equipment. Your baler needs internal components that can withstand contamination from dust and dirt in the cornfield. This may include special chains, pickup components or lubrication systems that help your baler hold up to tough conditions.

The pickup on your baler is going to take the most abuse from picking up stalks off uneven ground. Because of that, it’s important that your baler has heavy-duty pickup teeth. Rubber-mounted teeth work well for baling cornstalks because they provide more give and are less likely to break. In addition, durable, semi-pneumatic gauge wheels can help resist puncturing from the cornstalks in the field.

Overall, a heavily built baler is better suited to running through the cornstalks. Heavy-duty bearings in the rollers support the force in the bale chamber when running your baler at maximum density to achieve an acceptable bale weight with lightweight cornstalks.

You’ll also need to consider how well your baler can handle the ridges and rough terrain in cornfields. Look for a baler with high flotation tires because they’ll absorb shock and help minimize wear and tear on the machine.

Capacity and efficiency for cornstalk baling

A large volume of coarse material flows into the baler when baling cornstalks and corn stover. And because there is a tight window of opportunity to get cornstalks or corn stover baled, you are often trying to bale as many as possible in a very short timeframe.

Being able to get cornstalk bales started without hassle is key to your productivity in the field. This means your baler needs the capacity to handle very large volumes of coarse material and still run at a quick pace. Its pickup Its pickup should be built to withstand tough dirty conditions with minimum maintenance. It should also offer features that help reduce plugging that can happen when baling cornstalks.

When it comes to durability and efficiency, the Vermeer 605N Cornstalk Special baler is equipped to bale even the toughest crop quickly and efficiently. Watch how one Nebraska producer uses this baler to put up 10,000 bales of hay and cornstalks a year without breaking a tine.

Bale packaging for high-pressure cornstalk bales

As anyone putting up cornstalk round bales can attest, this material doesn’t stay together quite as readily as hay bales, and its higher density puts more pressure on the bale. Using strong, high-quality netwrap, like Vermeer net, can keep the bale wrapped tighter compared to using twine. It can save you valuable time and provide better packaging of bales. Compared to what you’d use for hay bales, you’ll use more netwrap to hold cornstalk bales together, so make sure you have plenty available to keep running. Depending on how you’re handling the bales, you may need three to four wraps of netwrap to hold one bale together.

Moisture matters when baling cornstalks or corn stover

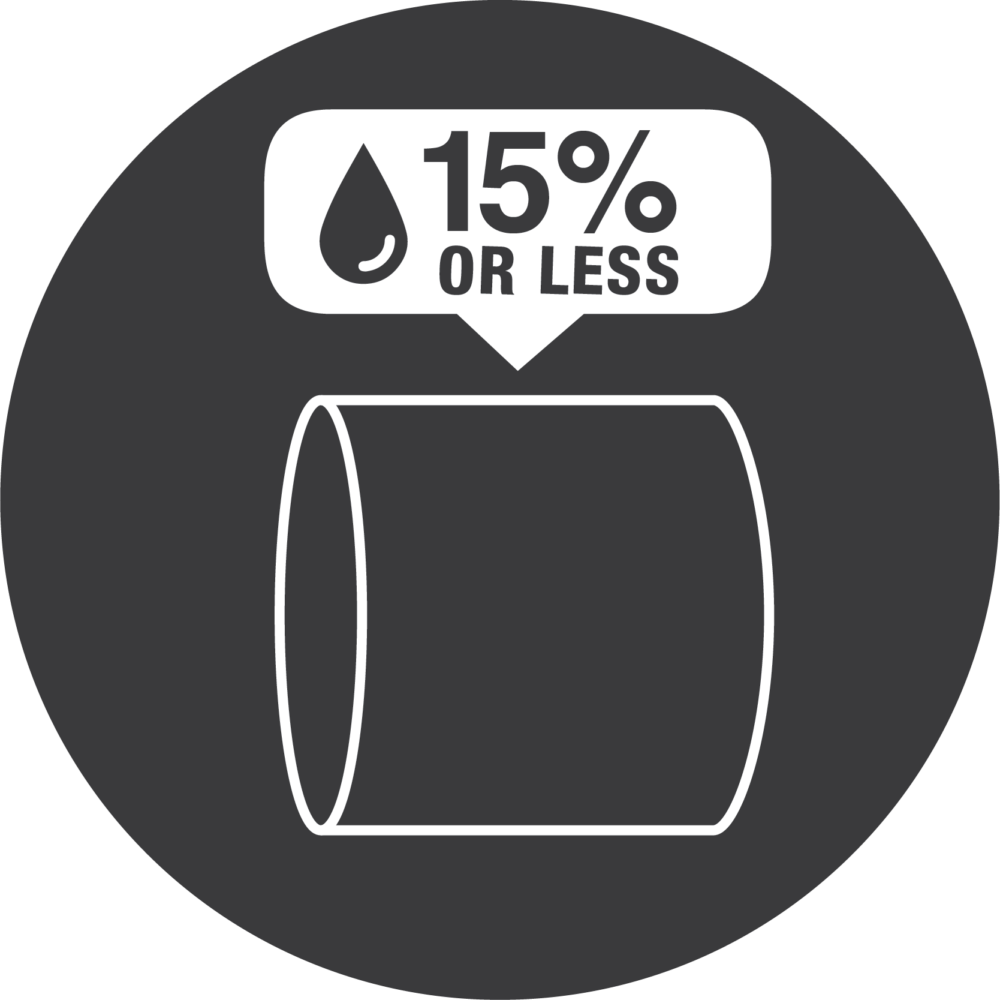

When baling cornstalks or corn stover, monitoring your moisture level is just as important as it is for any other crop. If cornstalk bale moisture is too high, you’ll deal with mold and other issues, just as you would with hay. Plus, baling heavy, wet corn stalks can cause more issues, such as plugging and bale shape problems. It’s important to make sure you’re baling at the proper moisture level — ideally around 15% moisture, just like dry hay.

Beyond the baler: rake considerations

Keep in mind that baling requires field preparation. Depending on what you plan to do with the stalks in the long run, that could mean raking the stalks before baling. As with your baler, durability is important to look for in rakes. The Vermeer VR1428 and VR2040 high-capacity wheel rakes handle cornstalks well. Built to last, these rakes combine heavy-duty construction and convenient maintenance with simple, tool-free adjustments. The lift/suspension cylinder on each wheel and nitrogen-charged accumulator make changing rake wheel settings and pressure quick when you’re out in the field. Watch the VR1428 and VR2040 in action.

Learn more about the equipment

To learn more about baling corn stalks and what equipment would be best suited to your operation, talk to your Vermeer dealer.